Electric Fuse and its Perfect Use

Table of Contents

ToggleAn electrical fuse is the simplest and most cost-effective safety device used to break the circuit. It is used to protect the electrical circuit during extreme overload or short circuits. An electric fuse is used in series in electrical circuits. In this article, you will learn in detail about the working principle, properties, types, advantages, and disadvantages of fuses.

What is an Electric Fuse

An electrical fuse is made up of a small piece of metal called a fuse wire. Tin, lead, silver, copper, zinc, aluminum, or alloy of lead and tin are used as fuse elements.

A fuse is a material having a low melting point that is placed in series with the live wire. Thomas Alva Edison invents the electric fuse.

When a short circuit or overload occurs in the electrical circuit due to some reason. So, this fuse material gets heated and melts due to excessive current flow, and the circuit breaks.

Lead and tin alloy are used in the ratio of 37% and 63% in circuits up to 15 A. Copper is used as a fuse element in circuits beyond 15 amperes.

Fuses are classified into classes such as CC, T, K, G, J, L, R, etc. The class letter indicates the interrupting rating, physical dimensions, and degree of current limitation.

Working Principle of an Electrical Fuse

The function of fuse in an electric circuit is on the principle of thermal effect. Under normal operating conditions, the temperature of the fuse wire materials is below the melting point. Therefore, the fuse wire carries the normal current without overheating.

When some fault occurs, like a short circuit or overload, the current exceeds the limiting value, this raises the temperature, and the fuse wire melts and breaks the circuit.

In this way, the fuse prevents damage to the machine and equipment from excessive current. The time for blowing out of the fuse depends on the magnitude of the current.

The fuse has an inverse time-current characteristic. In other words, the larger the current, the more rapidly the fuse will blow. An electrical fuse is used in the series circuit.

Fuse wires are generally used in high voltage up to 66kv and low voltage up to 400v. The material used for the fuse element has specific special properties such as:-

- Low melting point

- Low ohmic loss

- High Conductivity

- Low Resistivity

- Low cost

- Free from deterioration

Now, the thing is that all the qualities are not found together in any material. That is why some compromises have to be made to choose the proper electrical fuse. See, silver is excellent as a fuse material, but it is costly.

That is why, in ordinary form, mainly copper, lead, and tin are used. Tin, lead, and zinc have low melting points but also high specific resistance. Copper has a high melting point but low specific resistance.

Types of Fuse

According to the supply voltage, there are two types of fuse, a low-voltage fuse and a high-voltage fuse. Whereas, according to the current rating also, there are two types, AC fuse and DC fuse.

The categories of the fuse diagram flow chart are shown below so that you can understand the types of fuses well.

AC Fuse

AC fuses are used to protect AC circuits and appliances. It protects against both short circuits and overcurrents. Its size is smaller than that of a DC fuse.

AC fuse properties:-

- AC fuses are designed with voltage and current ratings to allow use over a specific range.

- The breaking capacity of the AC fuse is better without any damage.

- The time-current characteristic of the AC fuse is available in both fast-blow and slow-blow modes.

- Its arc suppression is better.

- It is safe from overheating.

DC Fuse

DC fuse is used for DC circuits, which is suitable for both short circuits and over currents. DC current flows in one direction, which is why it is difficult to extinguish the arc with a DC fuse. DC fuse is also bigger than AC fuse.

- DC current does not have a zero crossing point, so it is difficult to extinguish the arc.

- To extinguish the arc generated in the DC fuse element, arc-extinguishing materials such as quartz sand or ceramic are used.

- DC fuses also operate on fast-blow or slow-blow Time-Current characteristics.

- The breaking current of the DC fuse is high.

- The heat dissipation properties of the DC fuse are good.

Applications of DC Fuse

- Used in the automobile sector like cars, trucks, Electric Vehicles - EVs, etc.

- DC fuse is used in the protection circuits of the battery.

- DC fuse is used in Photovoltaic Solar Power Systems.

- This fuse is also used in telecommunication equipment.

- This fuse is used in DC motors, DC machines, etc.

Low Voltage fuses are of the following types:

1. Rewirable Fuse

It is used in small current circuits, mainly in household wiring. It is also called by various other names, such as semi-enclosed or kit Kat fuse.

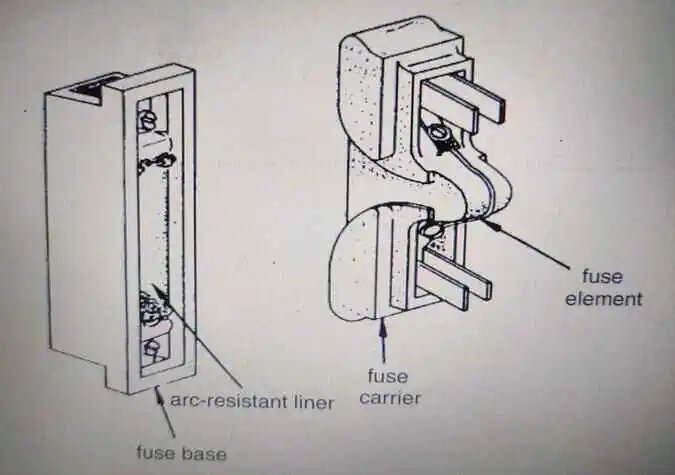

This fuse is made in two parts, one is the fuse case, and the other is the fuse carrier. Usually, this fuse is inside the fuse box.

The live or phase wires of incoming and outgoing contacts are connected in the fuse case. The fuse carrier holds the fuse conductor, which is also called fuse wire.

Cartridge Fuse

In this type of fuse, the fuse element is in a closed container with both sides connected by metal caps. It is of two kinds.

- D-type fuse

- Link type fuse

HRC Fuse

HRC fuse completely from high rupturing capacity cartridge fuse. This fuse is cylindrical in appearance, and its outer part is made of ceramic. The inner part is filled with quartz sand. Both ends of the fuse unit are connected to a brass cap, and the fuse element is attached to this cap.

HRC working principle:-When a fault occurs, the fault current flows through the fuse. Due to the flow of current more than the rating, the fuse element gets heated and melts. The fuse element chemically reacts with the ceramic sand to form high-resistance glass beads, and the circuit is broken.

High voltage fuses are of the following types:

High Voltage HRC Fuse

They are also similar to the low-voltage fuse. The only difference is that the fuse element inside it is coiled in a helix form. This is done to reduce the corona loss of the fuse. Inside the high-voltage fuse, two fuse wires are connected in parallel. One fuse wire is of high resistance, and the other is of low resistance.

Expulsion type Fuse.

This fuse is used for the safety of the feeder and transformer. This fuse is fitted inside the hollow tube in such a way that when the fuse is blown, the hollow tube falls down.

Advantages and Disadvantages of Fuse

Advantages :

- It does not require any maintenance.

- The cheapest way to get protection.

- Its operation is entirely automatic.

- It operates in both short-circuit and overload conditions.

- It is simple and reliable.

- Its replacement process is very easy.

Disadvantages :

- Fuse replacement is done manually, which takes more time.

- The protection of the whole circuit depends on this one fuse. If it fails for any reason, the entire circuit gets damaged.

Properties of Electric Fuse

Fuses are essential components in electrical circuits designed to protect equipment and prevent hazards by interrupting excessive current flow.

Understanding the characteristics of fuse is crucial for ensuring their proper selection, installation, and operation within electrical systems. Let us know about some special properties of the fuse.

1. Current Rating

The current rating of the fuse is one of the most essential characteristics. It specifies the maximum current that the fuse can safely carry without opening or failing.

Setting the current rating of the fuse to the standard operating current of the circuit ensures adequate protection against overloads and short circuits.

2. Voltage Rating

Electrical fuses have a voltage rating, which indicates the maximum voltage at which they can operate safely without arcing or failing.

A fuse of the correct voltage rating must be used in the circuit so that the circuit can be appropriately protected. The voltage rating of a fuse is specified by the manufacturer.

3. Speed of Operation.

Speed of operation refers to how quickly the fuse responds to a fault. Fuses are classified as either fast-blow or time-delay (slow-blow) based on their response time.

Fast-acting fuses react quickly to overload, while time-delay fuses tolerate a temporary surge before opening. Choosing the appropriate speed of operation depends on the characteristics of the load and the specific requirements of the circuit.

4. Interrupting Capacity:

The interrupting capacity of an electrical fuse defines its ability to safely interrupt fault currents without causing damage or creating a safety hazard.

Fuses with higher interrupting capacities can handle larger fault currents, making them suitable for applications with higher fault levels.

5. Temperature Tolerance

Fuse operates in a wide range of temperatures, from extreme cold to high heat. Therefore, they must possess adequate temperature tolerance to maintain their performance and reliability under varying environmental conditions.

Fuse with superior temperature tolerance exhibits consistent behavior and durability across different temperature extremes.

6. Physical Size and Form Factor

Electrical fuse is available in a variety of physical sizes and forms to meet different applications and installation requirements. The size and shape of a fuse determine its compatibility with fuse holders, electrical enclosures, and mounting configurations.

7. Indicator Features:

Many electrical fuses have been upgraded to provide a visual or audible indication when the fuse has blown.

These advantageous features allow for quick identification of fuse operation or facilitate troubleshooting and reduce downtime in electrification.

8. Material Composition

The materials used to manufacture fuses affect their operation and reliability. Common fuse materials include ceramics, glass, and various metal alloys, each of which offers specific advantages in terms of electrical conductivity, thermal stability, and mechanical strength.

Understanding these characteristics helps engineers, electricians, and maintenance personnel select the most appropriate electrical fuse, ensuring reliable protection and optimal performance in electrical systems.

Characteristics of Fuse

- low cost

- high conductivity

- low melting point

- free from deterioration due to oxidation

To understand the operation of the Fuse, consider some important points.

Current Rating of Fuse Element:-

Now, we see that in a fuse element, so many properties are not available at the same time. Alloy materials commonly used for small current rating fuse up to 15A.

For current exceeding 15A, this alloy is not used. Beyond 15A rating circuits, copper wire fuses are employed. The zinc strip is good and does not melt very quickly with a small overload.

Fusing Current :-

This is the minimum value of current which the fuse wire burnt. Obviously, its value is more than the current rating of the fuse element.. For round wire, the relationship between fusing current I and diameter d of the wire.

I=Kd^{3/2}

where K is a constant is called fuse constant. The smaller the length. this relationship shows

The Fusing Current Depends On The Following Factor

- diameter of wire

- size and location of terminals

- type of surface

- type of material used

- type of enclosure use

Fusing Factor :– It is the ratio of the minimum fusing current and the current rating of the fuse element that is known as the fusing factor.

It is always greater than unity. If the fusing factor is small, it is more challenging to avoid degradation due to overheating and oxidation at the rated carrying current. The fusing factor is equal to 1.9 to 2.0.

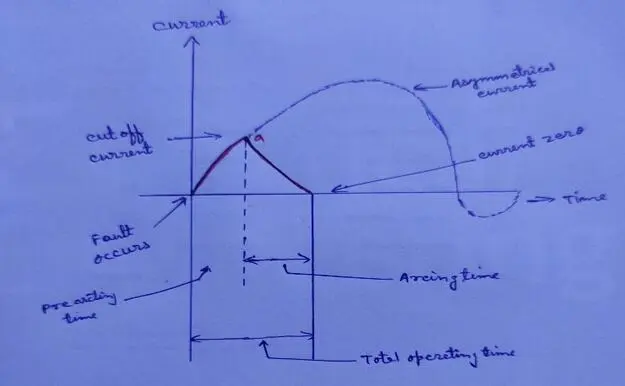

Prospecting Current :- The RMS value of the first loop of the fault current is called the prospective current. The fault current would typically have a substantial first loop; at this point, it generates sufficient energy to melt the fuse element.

Cut-Off Current:- The value of the current at which the cut-off occurs is called the cut-off value. When the fault occurs, the fault current has a giant first loop due to a fair degree of asymmetry. The heat generated is enough to melt the fuse element even before the first loop reaches the peak.

Cut Off Value Depends Upon

- current rating of fuse

- the value of prospective current

- asymmetry of short-circuit current

Pre- Arcing Time :-

It is the time between the commencement of the fault and the instant when the off occurs. In other words, the time from the start of the fault to the instant the arc is initiated is known as pre-arcing time. The pre-arcing time is 0.001 seconds.

Arcing Time :-

It is the time between the end of pre-arcing and the instant when an arc is extinguished.

Total Operating Time :-

It is the sum of pre-arcing and arcing times. The operating time of an electrical fuse is usually relatively low, say 0.02 seconds, as compared to a circuit breaker, say 0.05 seconds.

Breaking Capacity :-

The breaking capacity of a fuse is the rating corresponding to the RMS value of the AC component of the maximum prospective current and the system voltage.

Now, several types of electrical fuse are available that find extensive use in low and moderate-voltage applications. Electric fuses for the distribution system can be classified into ground-mounted and pole-mounted.

Ground-mounted fuse is usually contained within metal-clad switch gear and designed to protect a local ground-mounted transformer. They are rated up to 160 amps.

Pole-mounted electrical fuse for overhead networks can protect a local transformer. Still, it may also be installed at the start of a spur line to prevent faults on the spur line from affecting customers upstream of the fuses. Pole-mounted fuses are rated up to 40 amps.

Electrical fuses are small and relatively cheap, but they suffer from the disadvantage that they need to be replaced after every operation and before the load current can be again by suitable design and the use of metallic elements and filler materials. Different time/current characteristics can be achieved.

Conclusion

Electrical fuses protect devices by operating automatically when uncontrolled current flows in the circuit. With advancements in technology, modern fuses are currently being developed with increased efficiency and reliability. However, proper selection, installation, and maintenance are essential for optimal benefits. In conclusion, electric fuses play a vital role in various applications, ensuring smooth functioning and electrical safety.

A fuse is a device to protect appliances and wires in household electrical circuits from excessive electric current. It is a thin metal wire that is enclosed in a protective material. When the electric current exceeds the safe level, the fuse fitted in the circuit melts and breaks the circuit.

A fuse is provided in an electric circuit to protect electrical appliances.

A fuse works on the principle of heating effect of electric current.

The resistance of a fuse is low but not zero.

- 1A to 5A → For small appliances ( lights, fans, chargers)

- 6A to 15A → For medium appliances ( TVs, refrigerators)

- 16A to 30A → For heavy appliances ( air conditioners, heaters)

- Above 30A → For industrial and high-power circuits

I am an engineer in a government department and also a blogger. I write posts on topics related to electrical and electronics engineering.