Working Principle of Transformer in Simple Terms

Table of Contents

ToggleFunction of transformers as one of the basic electrical components which maintain essential roles during the movement and delivery of electric power from generation sites to end-users. A transformer operates as an electrical machine that conducts electrical power between multiple circuits through electromagnetic production. As fundamental electric devices transformers work to enable secure effective power transmission across extended distances while regulating voltage values to match various electrical devices and systems. This article states the working principle of transformers also explains their makeup along with the transformation process which matters in current electrical infrastructure.

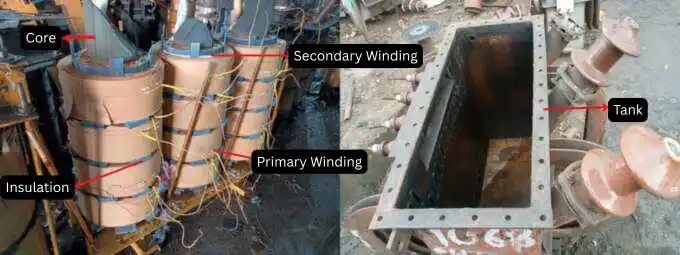

Main Parts of Transformer

- Core: Transformers require a core made of high-grade silicon steel laminations because this design reduces energy losses particularly those from eddy currents. The core enables magnetic flux generated by the primary coil to pass through it.

- Primary Coil (Winding): The alternating current (AC) enters through the primary coil that operates as the input component. The transformer core contains this coil which creates magnetic force when electric current runs through it.

- Secondary Coil (Winding): The output coil receives the designated name of secondary coil. Secondary windings surround the transformer core while carrying different numbers of loops in comparison with the primary coil. The load receives power through the current that is generated in the coil.

- Insulation: The windings receive insulation between each other and the core gets insulated protection to prevent electrical shorts while ensuring a safe operation of the transformer.

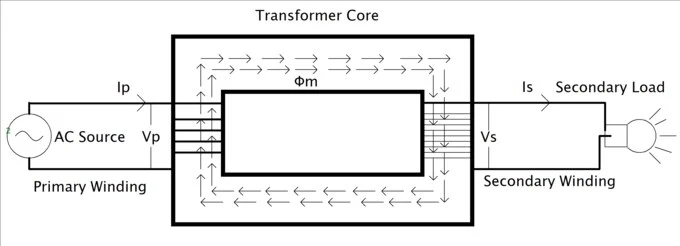

Working Principle of Transformer

The function of Transformer is based on the principles of Faraday’s induction law and Lenz’s law. A changing magnetic flux inside a coil induced electromotive force known as EMF in the coil according to Faraday’s law.

Lenz’s law demonstrates how an induced current always develops to fight against variations in magnetic flux according to its direction.

Alternating Current (AC)

Transformers require alternating current (AC) to operate because constantly varying magnetic fields produced by AC fulfill the requirement to generate secondary coil voltage.

DC cannot produce changing magnetic fields which renders transformers ineffective for powering with this type of current.

Magnetic Field Generation:

An alternating current (AC) passed through the primary coil of a transformer produces a changing magnetic field that surrounds this coil. The alternating current produces a magnetic field which develops and contracts according to the current direction changes.

Magnetic Flux Linkage

The magnetic flux that changes in time due to the primary coil transfers through the core material of the transformer. The laminated steel sheets found inside the core act as a guide to send magnetic flux toward the secondary coil. The core receives an engineered design for maximum magnetic permeability to enable unobstructed magnetic flux flow.

Induction of EMF in the Secondary Coil

The fundamental principle of Faraday’s Law of Electromagnetic Induction states that changing magnetic fields in a wire coil lead to the production of an electromotive force within the coil.

The flux emitted by the primary coil forms an interconnection with the secondary coil.The modification of magnetic flux produces an electrical voltage inside the secondary coil.

The measures of induced voltage derive directly from both the secondary coil turns count with the magnetic flux’s speed of change. The secondary coil produces a current because of the EMF it generates provided it exists within a closed electric circuit.

Voltage Induction

The resulting voltage in the secondary coil amounts to the product of primary winding turns relative to secondary winding turns. The number of turns in secondary and primary coils determines whether the circuit experiences voltage stepping up (increased) or stepping down (decreased).

Power Conservation in Transformers

A primary coil input of alternating voltage creates an alternating magnetic field within the core material. The secondary coil produces voltage due to Faraday’s Law of Induction as the magnetic field changes.

The number of coil turns in both primary and secondary sections defines the voltage strength that appears in the secondary coil. An ideal transformer functions without power loss through constant preservation of electrical energy.

Real transformers suffer from several efficiency losses which originate from copper resistances in the windings and magnetic field behavior in the core material.

Efficiency of Transformers

The performance measurement of transformers reveals the relationship between their output power and input power but is presented as a percentage value.

Operation of transformer for an ideal model results in optimal functioning because no power disappears throughout the power conversion process.

Real transformers endure three types of power loss known as copper losses together with core losses (also called iron losses).

- Copper Losses: The magnetic coil produces thermal energy from the power flowing through it because of resistance.

- Core Losses (Iron Losses): Hysteresis loss along with eddy current loss generate the losses which occur in the core region. Hysteresis loss occurs when the core material becomes magnetized and then demagnetized and eddy current loss arises from core-induced circulating electrical currents.

- Leakage Flux: A part of the magnetic flux created by the primary coil fails to form connections with the secondary loop structure. The leakage of flux through surrounding space reduces the efficiency of energy distribution.

The transformer operation achieves high efficiency levels due to built-in design elements that reach operating rates of 95% to 99%.

Types of Transformers and their working principle

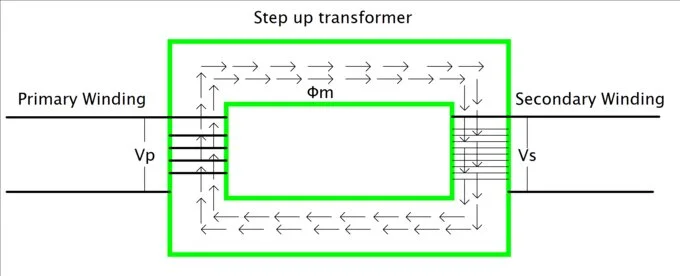

Step Up Transformer

An alternating current receives voltage level increase through implementation of a step-up transformer. The step-up transformer includes more turns winding on its secondary coil compared to the primary coil thus creating greater output voltage.

Tortious voltage transformations are regulated through the ratio equating primary coil turns to secondary coil turns. Units of the electrical grid rely on step-up transformers to preserve acceptable voltage strength during extended power transport.

Working Principle of Step Up Transformer

The power supply connects to the primary coil known as the input coil while the secondary output coil serves as the load connection point.

During primary coil current exposure an alternating current produces changing magnetic flux within the transformer core that creates enhanced voltage levels in the secondary coil through Faraday’s Law of Induction.

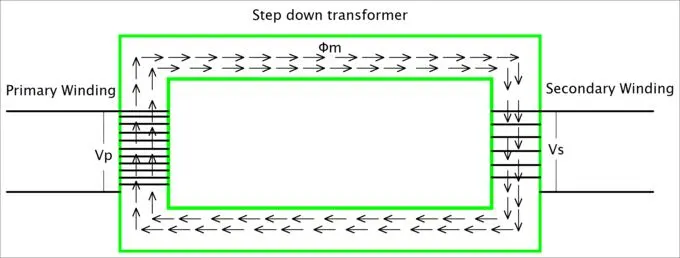

Step Down Transformer

An alternating current receives voltage level increase through implementation of a step-up transformer. The step-up transformer includes more turns winding on its secondary coil compared to the primary coil thus creating greater output voltage.

Tortious voltage transformations are regulated through the ratio equating primary coil turns to secondary coil turns. Units of the electrical grid rely on step-up transformers to preserve acceptable voltage strength during extended power transport.

Working Principle of Step Down Transformer

The power supply connects to the primary coil known as the input coil while the secondary output coil serves as the load connection point.

During primary coil current exposure an alternating current produces changing magnetic flux within the transformer core that creates enhanced voltage levels in the secondary coil through Faraday’s Law of Induction.

Single Phase Transformer

Single phase transformer also works on Faraday’s principle of electromagnetic induction. It has two windings, primary and secondary, which are insulated and wrapped on an iron core.

Single phase transformers are used to step down or step up the voltage in domestic and small industries.

Three Phase Transformer

The three-phase transformer serves to transform three-phase electrical systems that prevail within industrial facilities along with major commercial operations.

The voltage of three-phase power systems can be increased or decreased through three-phase transformers making them superior for electric power transmission.

Working Principle of 3 Phase Transformer

Each phase of the three-phase transformer system uses an individual separate winding. The windings function together in perfect synchronization to both increase and decrease voltage levels across every phase leading to balanced power delivery.

Isolation Transformer

A device needs an isolation transformer to maintain an isolated connection from its power source. The transformation function of this device does not adjust voltages but serves to separate the electrical paths between its primary side and secondary side.

An isolation transformer serves three essential functions: it protects equipment from electrical shock, reduces power-related noise interference and generates a steady power supply for delicate systems.

Isolation Transformer Working Principle

An isolation transformer functions by preserving the identical ratio between its primary and secondary winding voltages. The transformer does not modify the voltage level but it separates the secondary electrical pathway from the primary.

Autotransformer

An autotransformer functions by using one winding as both primary and secondary parts. An autotransformer adopts one winding mechanism instead of distinct windings to create an improved and reduced design.

Auto Transformer Working Principle

During operation an autotransformer delivers some input voltage directly to the load yet adjusts remaining voltage by using the common winding section.

The efficient design enables lower losses thus making these transformers superior to conventional ones for some application scenarios.

Toroidal Transformer

A toroidal transformer takes a ring-shaped form instead of utilizing typical rectangular or square cores for transformation purposes.

A continuous wind of ferromagnetic material makes the core which the winding encircles. Toroidal transformers possess both small size characteristics and operational efficiency features.

Working Principle of Toroidal Transformer

The operation of toroidal transformers proceeds according to the traditional transformer working mechanism involving electromagnetic induction.

The toroidal design provides both a high efficiency rate along with decreasing stray magnetic field strength that results in minimal power waste and interference.

Pulse Transformer

A pulse transformer functions as a device which delivers electric pulses rather than handling consistent signals.

Such devices operate for fast switching of high voltages within radar systems alongside communication systems as well as applications that need pulse transmission.

Telecommunication systems depend on pulse transformers to properly transmit high-frequency signal signals efficiently. The design of pulse transformers facilitates digital signal conversion during control system operations along with signal processing duties.

Working Principle of pulse Transformer

A pulse transformer produces quick voltage variations through its pulse output mechanism. The design of the device specializes in transmitting rapid brief high-frequency signals which set it apart from other transformers that process consistent currents.

Instrument Transformer

The proper calculation of electricity usage depends on instrument transformers which provide current and voltage measurements for electric circuits during billing procedures.

The devices operate within power grid protection systems to monitor circuit faults by measuring both current and voltage levels.

Working Principle of instrument Transformer

The Current Transformers (CTs) lower high current levels to measurement-ready values that are usable by meters and relays to prevent harmful exposure to sensitive equipment.

Voltage Transformers (VTs) provide power utilities with the functionality needed to transform high voltage levels down to lower levels suitable for control system monitoring operations.

Conclusion

The operation of transformers depends on electromagnetic induction because a varying magnetic field in the primary coil generates voltage in the secondary coil. The number of coils determines how transformers either raise or lower voltage to enable effective power transport systems.

I am an engineer in a government department and also a blogger. I write posts on topics related to electrical and electronics engineering.